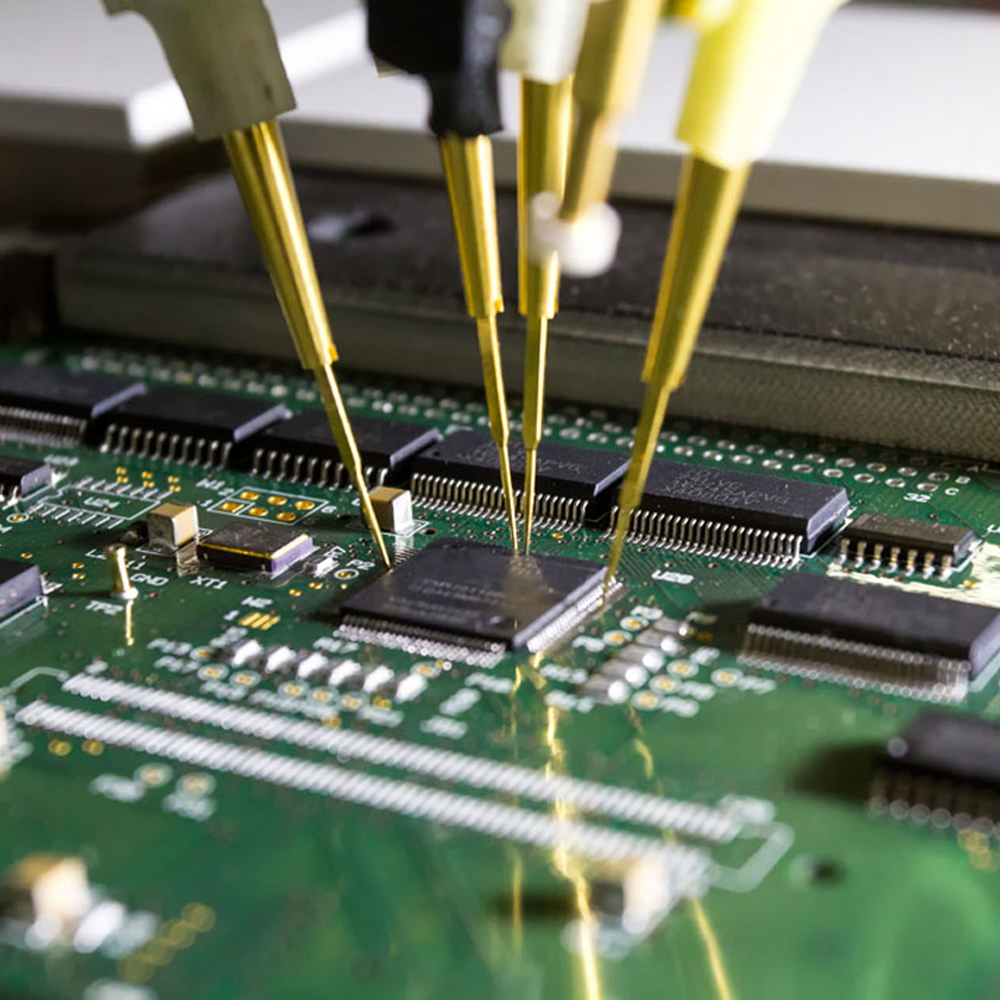

Our spare parts warehouse has a wide range of SIEMENS and FANUC electronic parts for NC, PLC and Drives.

The stock includes over 5000 electronic parts with immediate availability for our customers.

In order to offer a service that is increasingly attentive to cost reduction, we have not only new components but also reconditioned spare parts. The range of available products covers automation systems that go from the first CNCs to the most modern equipment, protecting our customers from the risks of obsolescence.

All the material is supplied with a 12-month warranty.

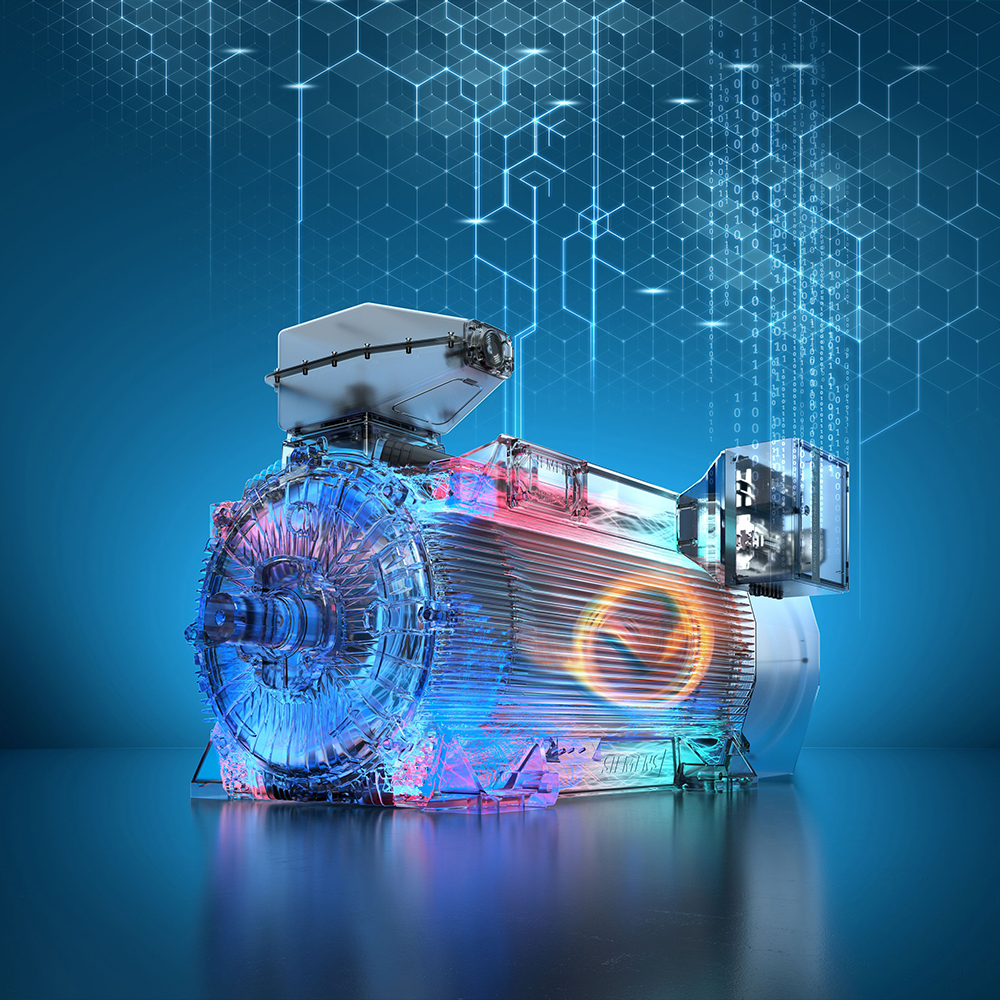

The motor warehouse:

The motor warehouse is stocked as for the electronic spare parts of new and overhauled SIEMENS and FANUC products, always covered by warranty.

The motors in stock cover needs of all types, and if not available, we can carry out any adaptation at our laboratory to create the desired motor.

The range of motors available to our customers covers every need, from the first DC motors to the most modern linear motors.

Modern engines are supplied with their integrated electronics already reprogrammed with the data of the faulty engine so that they can be replaced without difficulty.